Physical Adsorption

WARNING: Look at the warning at the page's bottom.

Background:

Physiosorption is the process by which atoms adhese to a surface through the van der Waals force. The atoms layer onto the surface until they completely cover the surface area. Then a new layer will be started and so on. As each layer is set upon the previous layer, the distance between the original surface and the outer most layer increases. The van der Waals force is weak so this distance limits the theoretical amount of surfaces to roughly 7 or 8, depending on lab conditions. Normally, a porous material is required for physiosorption to be seen in the lab, graphene, for example. The system that holds the porous material must be in a low pressure and cold temperature environment. The cold temperature is for condensation, and physiosorption, to occur.

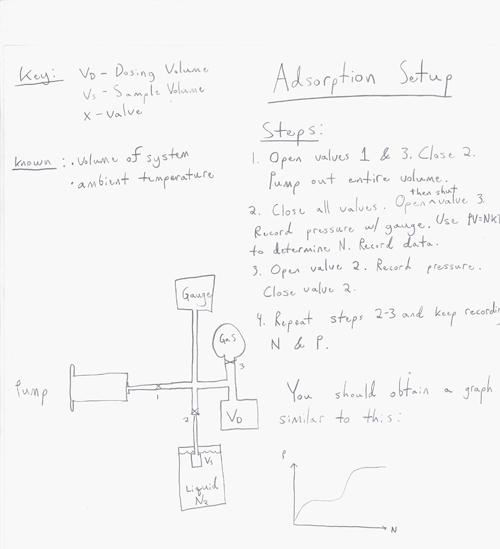

This project aims to create an apparatus that will show the effects of physiosorption on a porous material. Here is a rough sketch of the general idea:

The apparatus is mostly read to be put together. All of the parts have already been ordered and are available. There still needs to be work done on connecting all the pipes together and for the whole system to be structurally stable. This will most likely be done by attaching four support legs so that the setup can be lowered over a tank of liquid N2 and allowed to stand. The system's volume also needs to be calculated. The idea of using water to fill all of the pipes/systems was thrown around.

If you are able to proceed to collecting data, don't expect to achieve more than one adsorption step on your P/N graph. Our lab conditions are not perfect.

WARNING: This project has a vital piece that needs to be apart of the design no matter what: the vent off valve. Ask the metal shop or Bryan for help identifying this piece. This is the piece that keeps the sample volume from turning into a bomb. It's purpose is to vent off excess pressure so that no compartment feels pressure stress.