Operating a Metal Lathe

Permanent Materials

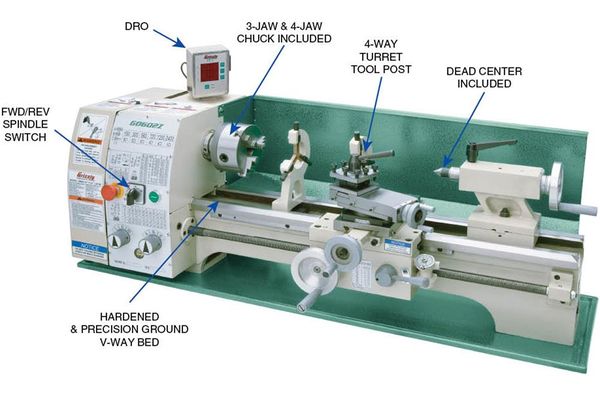

- G0602Z Lathe and Tool Bits - Tailstock Chuck and Drill Bits - Cutoff Tool - Digital Calipers

Consumable Raw Materials

- Al 6061 3/8" Diameter Rod Stock (for 1/4-20 screw) - Al 6061 5/16" Diameter Rod Stock (for 8-32 screw)

Activities

Basic Idea: Make a 1" 8-32 or 1/4-20 Fully-Threaded Flathead Screw with Chamfered Tip from rough stock.

CLEAN UP AREA AFTER EACH LAB SESSION

NOTE: Apply oil to ball oilers at start of machining session

- Get a safety demonstration from the instructor or TA.

- Read the G0602Z manual Introduction and Safety sections (pages 3-13) and the Operations section (pages 25-48). You can also view a few of the many good how-to-lathe videos on YouTube.

- Read the Wikipedia page on Screw Threading. Take a look at the ANSI External Screw Thread Size and Tolerances Chart.

- Use AutoCAD (on virtual machine on mother in APL) to make a technical drawing of a 1" 8-32 or 1/4-20 fully-threaded flathead screw with chamfered tip. If you're new to AutoCAD you can view a few of the many good AutoCAD-for-beginners tutorials on YouTube. Show drawing to Instructor or TA before moving on.

- Read the Wikipedia page on machining speeds and feeds. Calculate Spindle Speed with this online calculator. Verify that the lathe's current spindle speed is less than or equal to the calculated spindle speed. If not, discuss with the instructor or TA (DO NOT ATTEMPT TO CHANGE THE SPINDLE SPEED OR GEARING YOURSELF).

- Set up a rough cut of an appropriate length of round Al stock with which to make a screw with the bandsaw - Get instructor or TA approval before making the cut. Clean up metal shavings and put bandsaw and stock back in storage areas.

- Mount the rough stock in the lathe chuck (rough side facing out). Get instructor or TA approval before facing off the rod.

- Face off the rod.

Skills:

- Facing

- Turning

- Threading

- Parting