Fiber Optics

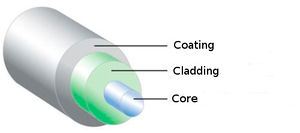

Fiber Basics

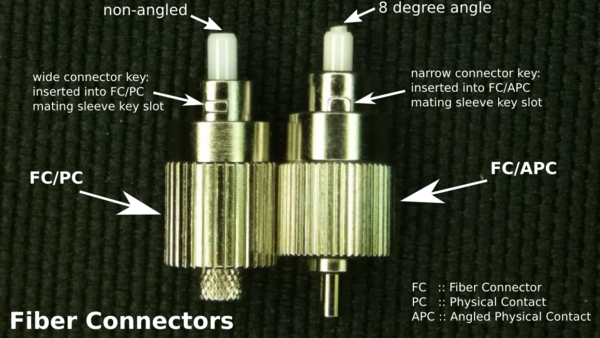

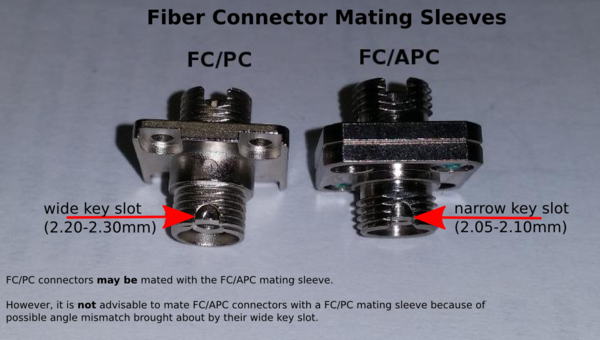

Connectorizing optical fiber

Remember to practice safety when breaking fiber and handling broken ends: wear safety glasses and tape up ends

The following list discusses the highlights of connectorizing fiber. Consult Thorlab's Fiber Polishing and Connectorization Manual for a more complete description.

- Strip coating from fiber, leaving 2-3 inches of bare fiber

- Prepare epoxy (EpoTek 353ND, mixing ratio 10:1 A:B by weight)

- Inject epoxy into connector

- Insert bare fiber through ferrule and cure epoxy (20 min @ 120 C, or level 6 on our oven)

- Use diamond tipped blade to score and cleave fiber just above epoxy bead

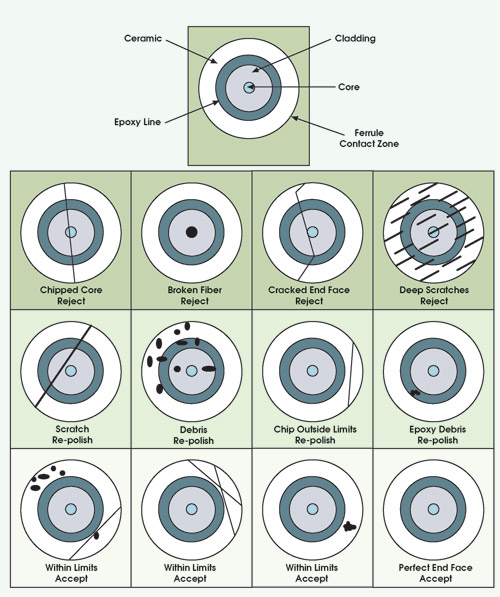

- Hand polish tip until fiber is flush with epoxy

- Polish using abrasion sheets and polishing puck: 30um (green), 6um (yellow), 3um (red), 1um (white)

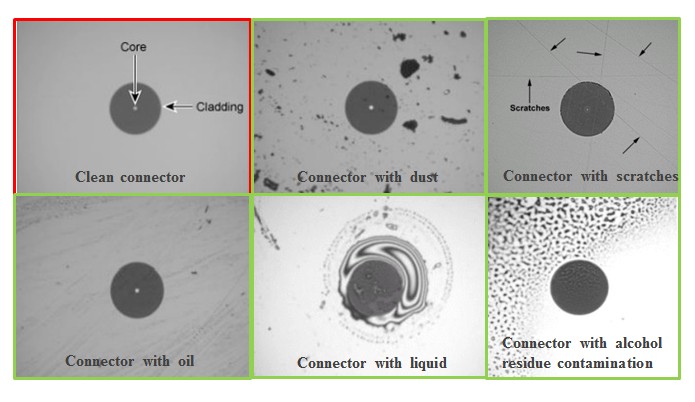

Some useful fiber polishing pictures

Other useful links:

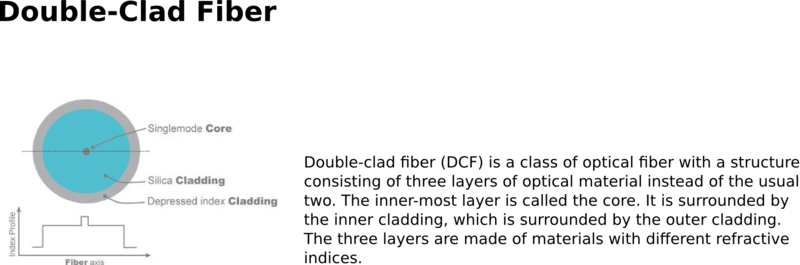

Double-Clad Fibers - Wikipedia

RP's Passive Fiber Optics Tutorial