Graphene as Saturable Absorber

Mode Locking with Saturable Absorbers

Passive mode-locking techniques are those that do not require a signal external to the laser (such as the driving signal of a modulator) to produce pulses. Rather, they use the light in the cavity to cause a change in some intracavity element, which will then itself produce a change in the intracavity light. A commonly used device to achieve this is a saturable absorber.

A saturable absorber is an optical device that exhibits an intensity-dependent transmission. What this means is that the device behaves differently depending on the intensity of the light passing through it. For passive mode-locking, ideally a saturable absorber will selectively absorb low-intensity light, and transmit light which is of sufficiently high intensity. When placed in a laser cavity, a saturable absorber will attenuate low-intensity constant wave light (pulse wings). However, because of the somewhat random intensity fluctuations experienced by an un-mode-locked laser, any random, intense spike will be transmitted preferentially by the saturable absorber. As the light in the cavity oscillates, this process repeats, leading to the selective amplification of the high-intensity spikes, and the absorption of the low-intensity light. After many round trips, this leads to a train of pulses and mode-locking of the laser.

Considering this in the frequency domain, if a mode has optical frequency ν, and is amplitude-modulated at a frequency nf, the resulting signal has sidebands at optical frequencies ν − nf and ν + nf and enables much stronger mode-locking for shorter pulses and more stability than active mode-locking, but has startup problems.

Saturable absorbers are commonly liquid organic dyes, but they can also be made from doped crystals and semiconductors. Semiconductor absorbers tend to exhibit very fast response times (~100 fs), which is one of the factors that determines the final duration of the pulses in a passively mode-locked laser. In a colliding-pulse mode-locked laser the absorber steepens the leading edge while the lasing medium steepens the trailing edge of the pulse.

In particular, graphene can be saturated over the visible to near-infrared region and it has a smaller non-saturable loss and higher damage threshold.

Application of Graphene to the Tip of a Fiber Connector

We want to use graphene as a saturable absorber for our MOPA

In order to do that, we need to get graphene onto the tip of a fiber connector:

Cut Out a Small Square From the Graphene Sample

To cut the graphene sample, use an exacto blade and press firmly onto the foil, no sawing motion

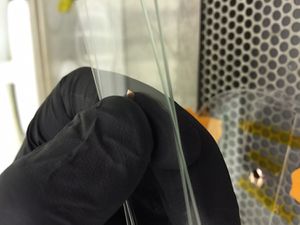

Once the small square is free, place it onto a glass slide and with another glass slide cover it

Press the two slides together to flatten the foil so that hopefully the suction in the next step will be strong enough to hold it in place

Put a Droplet of Isopropyl Alcohol onto the Copper Square

Careful not to wet the copper square, a bead is needed in order to adhere to the target substrate

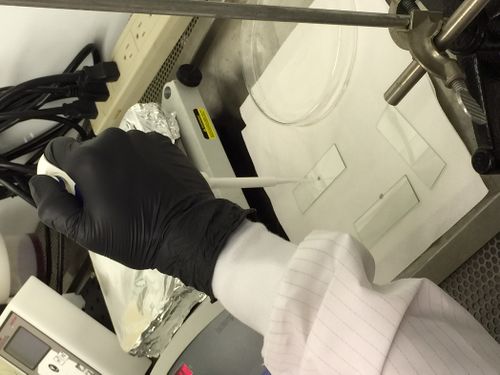

Once there is a bead of Isopropyl on the copper square, lower the fiber connector slowly down to it. We used a translation stage to lower the fiber connector down slowly and smoothly

When the tip of the fiber connector breaches the top of the bead, the copper square should be sucked upward and flatten on the surface of the fiber connector tip:

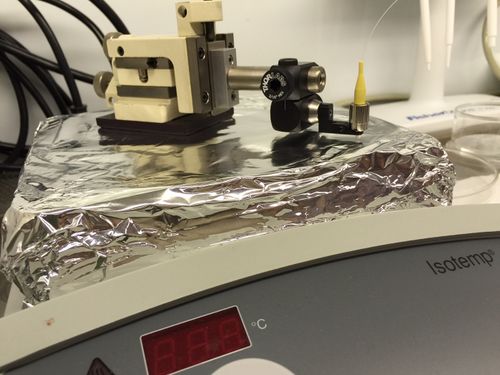

Bake the Fiber Connector on a Hot Plate

Place the whole translation stage onto a hot plate set to 120C

Lower the translation stage so that the tip of the fiber connector is right above the hotplate

Let it bake for an hour and a half:

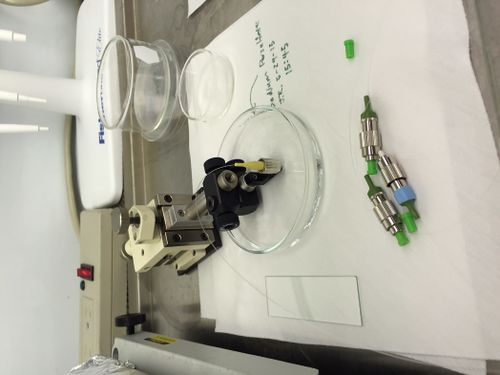

Etch the Copper Substrate

Fill a glass petri dish with copper etchant (we used sodium persulphate)

Lower the fiber connector tip into the copper etchant slowly

Let it sit for an hour, and then dip the fiber connector into DI water the same way to remove excess etchant: