Erbium-Doped Fiber Amplifier & CW Laser

The goal of this project is to construct a high power fiber laser using double-clad fiber co-doped with erbium and ytterbium. Then to optimize the fiber laser, altering the length of the gain medium and the output coupling ratio to maximize output power.

Background

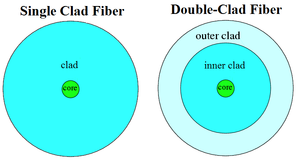

Optical fiber comes in two common types: single-mode and multimode, each with their own advantages and drawbacks. Single-mode fiber allows for higher beam quality with low propagation loss, but requires single-mode pump sources, which tend to be lower power and more expensive. Multimode fiber allows the use of higher power and less expensive multimode pump sources, but sacrifice beam quality and propagation loss in the process.

Double-clad fiber, however, offers the best of both fibers. Like its name suggest, double-clad fiber has two claddings, along with single-mode core. Double-clad fiber offers high beam quality with low propagation loss of the signal in the core, but supports higher power and less expensive multimode pumping of the inner cladding.

Fiber Laser Construction

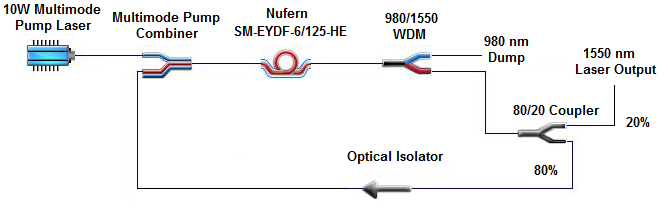

Our double-clad fiber ring laser, like all ring lasers, uses a positive feedback loop into a gain medium to achieve lasing. A 10 W 975 nm multimode laser diode is coupled into the inner cladding of the active fiber us a multimode pump coupler. The active fiber is co-doped with erbium and ytterbium. The erbium absorbs the pump light and emits 1550 nm light through the core, while the ytterbium only serves to increase the efficiency of the energy transfer. The signal light propagates through the core and into a coupler, where the majority of the light is sent through the feedback loop. An optical isolator in the feedback loop ensures light only propagates in one direction to reduce any possible loss. The feedback light is then sent into another end of the multimode pump coupler, where it is coupled into the core of the erbium-ytterbium doped fiber (EYDF) where it causes stimulated emission. The remaining portion of the signal light that is not returned as feedback exits the system as the output of the laser.

Controlling the Pump Laser

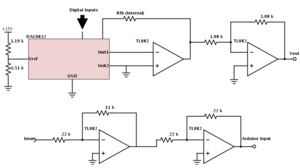

To power our pump laser, we are using a laser diode driver which drives 0-15 A based on a supplied 0-10 V signal. To control the signal, we created a graphical user interface using Python, with the modules Tkinter and PySerial, as well as an Arduino Duemilanove. The GUI allows us to set a 0-8 V signal (so as not to surpass the 12 A current limit of the diode laser) with 8-bit resolution using a digital-to-analog converter. All of these components were then built into a box to allow for simple operation of the laser diode.

Initial Results

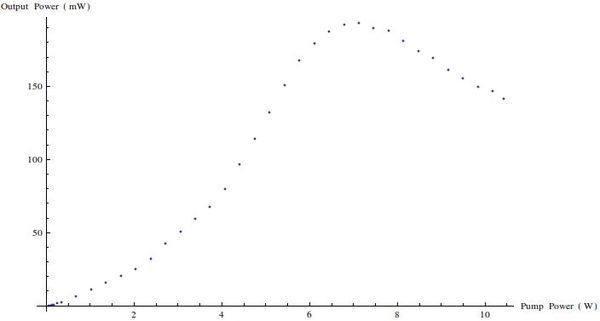

After constructing the fiber laser, using an 80/20 output couple and 1.5 m of active fiber, we were able to measure the output of the laser in response to the pump laser power. We discovered the laser had an output power of 140 mW with the pump laser at 10 W. But when the pump laser is at 7.1 W, the laser has an output power of 190 mW. We expect we are saturating the erbium-ytterbium co-doped fiber, but that would result in a gain curve which plateaus, not decreases. Investigating other high power lasers, we found a common loss mechanism is Stimulated Brillouin Scattering (SBS). SBS is a nonlinear loss mechanism that increases with pump power and temperature. This means that once we hit max gain on our EYDF, the increased effects of SBS force our laser's output power to decrease. But this is only a hypothesis, and must be tested in the future.