General Lab Equipment Obstacle Course

A general primer in important equipment in a scientific laboratory.

Contents

Multimeters

This module will teach you about how to use the Fluke 179 True RMS multimeter. For this, you will need:

- Rigola DP1308A DC Power Supply

- Rigola DG1022 Function Generator

- An assortment of short wires

- 3 Resistors: 500ohm, 1kohm, 2kohm

- 3 Capacitors:

- A diode: one 1N4148

- A breadboard (or protoboard)

- BNC-Banana Plug Adaptor (with male BNC plug)

- BNC Cable

You'll learn more about the Power Supply and Function Generator later, but we'll need a minimum of functionality from them to make measurements with the multimeter.

- Measuring voltage

Connect two probes to the right most inputs to the multimeter. I would recommend using probes with pointed tips or alligator clips at the end. The bottom input is the common/ground input and the upper right input is the voltage/resistance/diode. input. For simplicity, I'll refer to the probe connected to the voltage/resistance/diode input as the "red" probe and the probe connected to the ground input as the "black" probe. Turn the dial on the multimeter so that it points to V (with a line/dashed line over it) . This mode measures constant (DC) voltages, or will measure the RMS voltage of an alternating current. It measures the voltage difference between the top input and the common input (Vmeas = Vtop - Vbottom).- To verify this, touch your two probes together. What does the meter read? Does this make sense? What is the voltage difference between two points without any resistance between them?

Now, turn on the power supply. Hopefully, the yellow box on the screen will be highlighted. If not, press the +25V button on the power supply (above the yellow line) to change to that output. Press the left most button under the screen, so that VOLT is highlighted. This will give you control over the voltage output of the power supply. You can verify this by seeing that one of the numbers in the voltage box has turned white.

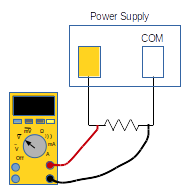

Connect the positive output of the power supply (yellow) to one row of inputs on the breadboard and the common output of the power supply (labelled as "COM") to another row. Between these two rows, plug in the 1kohm resistor.

Turn on the yellow output by pressing the center ON/OFF button (under the yellow box). The black OFF box at the top of the yellow window should change to a green ON box. Use the right/left arrows on the directional control buttons to highlight the tenths digit of the voltage line. Use the up/down buttons to change the voltage output to 00.50V. The box should be out putting half a voltage now.

- To verify this, touch the red probe to one end of the 1kohm resistor and the black probe to the other end. What does the multimeter read (as shown to the right)? If it reads 0.00, make sure the connections to the power supply are secure.

- If you flip the locations of the probe, what do you think will happen? Take a guess, then try it.

Replace the 2kohm resistor with the 500ohm resistor and 2kohm resistor in series (that is, end-to-end so current flows through one and then the other).

- Using your knowledge of resistors in series, what do you think the voltage dropped across the 500ohm resistor will be? What about the 2kohm resistor?

- Measure the voltage across each resistor separately (place the probes on either side of one resistor, then on either side of the other). Were your guesses correct?

Change the dial on the multimeter to the mV symbol with the line and dashed line over it. This is the millivolte measuring mode. It measures voltages the same as the voltage mode, but it reports results in millivolts and gives more accurate measurements for small voltages.

- Measure the voltages across the resistor pairs again. Do you get what you'd expect in mV?

- Measuring current (check that fuse isn't blown!)

- Based on what you know about electronics, how much current should traveling through the resistors?

- As mentioned above, current measurements are done in-line. To do this, break the connection between the two resistors. Touch one multimeter probe to the free end of one resistor and the other probe to the free end of the other resistor (as shown to the right). Does the reading agree with your prediction?

- Switch the probes. How does the current measurement change? Does this make sense?

- Measure the total current drawn from the power supply. To do this, attach one multimeter probe to the the output of the power supply and the other probe to the ends of both resistors.

- Now measure the current through just one of the resistors in parallel. To do this, unattach one resistor from the probe and attach the free end directly to the power supply line.

- Using what you know about current, predict the current in the other resistor. Then measure it. does your measurement match your prediction?

- Measuring resistance and testing for continuity

- Without the probes touching, what does the meter read? 0L stands for No Load - there is no electrical contact between the two probes. Technically, the multimeter can measure resistances up to 50Mohm, so 0L really indicates the resistance is greater than this value.

- What do you think the multimeter will read if you touch the two probes together? Try it. Does your answer agree with the probe? A non-zero resistance is okay, as long as it is very close to one. The probe can report resistances down to 0.1 ohm, so hopefully your result is close to that.

- Touch the probes to both sides of each resistor. Do the resistances that multimeter gives you agree with what the resistors say their resistances are? If not, does the multimeter measurement agree to within the tolerances listed by the resistors?

- Combine some resistors in parallel and series. Calculate what you believe the total resistance should be with a given combination. Does the multimeter agree with your calculation?

- Touch the probes together. What did the meter do?

- Touch the probes to either side of the 1kohm resistors. What did the meter do?

- Touch the probes to either side of the 10ohm resistor. What did the meter do?

- Diode check

- Test that your diode functions correctly. Flip the probes, and check that the fluke does not beep.

- If the multimeter has an extended beep, the diode is bad and there is a short in it. You can simulate this by touching the two probes together.

- When testing the diode and it beeps, the multimeter will show a voltage on the screen. What do you think this voltage is?

Unsure? Look through the diode's datasheet (available here).

Still not sure? Warm the diode by squeezing it between your fingers. How does the voltage measurement change as the diode heats up? Are there any properties of the diode that the data sheet indicates should change in the same way with temperature that you are observing? - AC signals, frequency response

- Press the 2nd (from the left) blue button under the screen to change the amplitude of the signal. The amplitudes are given in peak-to-peak voltage, this is the voltage between the bottom of the wave and the top of the wave. How does this compare to the amplitude of the wave? Set the function generator to produce a wave with an amplitude of 0.5V.

- Turn the dial to the V with a "~" above it. This puts the multimeter in RMS voltage measuring mode. BEFORE you measure the output of the calculate what RMS voltage you expect from a sine wave with an amplitude of 0.5V.

- Voltages are output from the BNC connectors on the right side of the function generator. Connect the output for channel 1 (lower one) to the multimeter. Does the RMS voltage that the multimeter agree with your answer above?

- How does the RMS voltage scale with the frequency?

- How does the change in RMS voltage compare above and below 1kHZ? How about above/below 500Hz? How do these voltages compare to your estimated RMS voltage?

- Look at the multimeter's data sheet (or manual) and find the accuracy rating of the multimeter for measuring AC voltages. Does your estimate for the RMS voltage fall into the accuracy range of the measured result?

- Press the yellow 2nd button while in RMS voltage mode. Does this frequency agree with what you set the function generator to? Change frequencies and verify these are performing correctly.

- How large can you make the frequency before the multimeter stops performing correctly? Is this about the correct range that the multimeter's data sheet gives?

- Unplug the BNC-banana plug adaptor and flip it around, so the plug with the GND tag is in the voltage/Resistance/Diode input of the multimeter. Does that change your RMS voltage reading? Does how it changed make sense?

- Press the Square Wave button next to the sine wave button. This should create a square wave output. Does the RMS voltage agree with what you'd expect for a square wave?

- The ramp output of the function generator (next to the square wave button) makes a triangle wave. Does the RMS voltage you measure agree with your prediction?

- Put the multimeter into frequency measuring mode and see if it can measure the frequency of square waves and ramps.

- Capacitance

- Clamp meter

- Temperature Measurements

To measure current, you need to use either of the left inputs and the common input to the multimeter. Both of the left inputs measure currents that flow INto these inputs and then OUT of the common input (black probe). This means the multimeter must be in-line with the current to measure it. The top-left input measures currents up to 400mA and the bottom one can measure currents up to 10A. The dial on the multimeter must be turned to the A (with line and dashed line) setting or the mA (with line and dashed line) setting. Like voltage, one will measure in A and the other in milliamps.

Change the multimeter to the milliamp setting. You'll note that on the right side of the screen, it will say "AC" under the unit listing ("mA"). Then, the meter will tell you the RMS current of an AC signal. This isn't what we want. Press the yellow 2nd button. The multimeter will beep and change to "DC" mode. This will report the DC current that flows through the multimeter.

Now, put the 1kohm and 2okhm resistors in parallel between the power supply lines.

The multimeter can be used for measuring resistance and for testing line continuity, that is checking that two points in a circuit are connected electrically.

Resistance measurements are straight forward. Attach the black probe to the common input (lower right) and the red probe to the voltage/resistance/diode input (upper right). Turn the dial to the resistance setting (capital greek letter Omega, Ω). Touch the probe ends to two points and the meter will read the resistance between the two probes.

The continuity test is similar to the resistance test. The multimeter will beep if there is electrical contact between the probes and the meter will report the resistance between the probes. Turn the dial to the symbol that looks like 4 right parentheses to use that mode.

The continuity mode is nice as you do not need to read anything, you can just listen for the beep. This is a good way to tell if components are connected correctly while soldering. However, as you hopefully observed, even if there is some resistance between the points the meter can beep - the multimeter's manual says that you will get a beep for resistances below 25ohm. This is sometimes problematic and you should instead measure the resistance. For example, if you think you have broken a resistor by running too much current through it, the resistor may still have some resistance and not trigger the multimeter's continuity test, but it's resistance has still fallen below what you need it to be for your application. Just relying on the continuity test to tell you if the resistor is good or bad is not sufficient.

The multimeter can be used to check diodes. Turning the dial to the continuity test mode (4 right parenthesis) then press the yellow 2nd button until a diode symbol appears on the screen. The red probe should be in the Voltage/Resistance/Diode input (top right). Touching the red probe to the annode side of the diode and the black probe to the cathode side of the diode should result in a beep from the multimeter, if the diode is functioning correctly.

For this portion, you will need to use the Rigol DG1022 function generator. Turn it on and press the two output bottons (on the right side) so that only the bottom one is lit, this turns on only channel 1. This should be reflected on the display with "ON" written in the top right of box for channel 1 and "OFF" in the box for channel 2. If channel 2 has a black background on the display, press the CH1|CH2 button (just to the left of the 0 in the number pad) to change which channel you are adjusting. Press the left most blue button under the display to select frequency setting mode. Use the dial (and the right/left arrow buttons next to it) to change the frequency to be 4kHz.

Press the "Sine" button in the bottom left corner of the function generate to create a sine wave output from the function generator.

Unplug probes from the multimeter. Plug the BNC-banana plug adaptor into the two right side multimeter inputs. The banana plug with an extra "tab" on its side should go into the COM input.

The multimeter does not read the RMS voltage of all frequencies the same. It has a certain frequency response. To see this, press the left most blue button under the screen to go to frequency adjusting mode. Slowly change the frequency of the output wave to a bunch of different values.

The multimeter can also read frequency.

Put the multimeter back into RMS voltage mode (press the yellow 2nd button again) and decrease the frequency so the voltage reading is valid.

The function generator can output other waves than just sine waves - and the multimeter should be able to measure them. What kind of RMS voltage would you expect for a square wave with an amplitude of 0.5V? What about for a triangle wave?

The multimeter can also measure RMS current. To do this, you must have the probes set up correctly to measure current and the dial should be set to one of the current modes (see above). The current mode defaults to AC mode, so it with report the RMS current through the multimeter automatically (recall we had to press the yellow 2nd button to read DC currents earlier). If you press the yellow 2nd button twice (so that "Hz" appears on the display), you will be able to measure the frequency of the current.

Power Supplies

- Digital and Analog

- Floating and grounding

- Current/voltage limiting

Function Generators

(Should look at this in tandem with the following oscilloscope discussion)

- Frequency, amplitude, offset, phase

- Frequency sweep/ramp

- Sine, square (incl. TTL), triangle, sawtooth, arbitrary waveforms (possibly a demonstration of Fourier components)

Oscilloscopes

- Voltage/time scale

- Coupling

- Triggering

- Scope probes

- Termination

- Bandwidth, sampling

- Aliasing

- Analyzing data: cursors, averaging, math menu

- Exporting data

- Analog and digital scopes

RF Signals

- Measuring RF power

- Termination and impedance matching

- Attenuation and filtering

- Splitters, mixers, and switches

Lock-in Amplifier

- Basic idea of operation; reason for using

- Use switch to turn on and off a highly attenuated signal and detect it with the lock-in

Frequency Counters

Measure the frequency of an RF source; map frequency vs. voltage curve of a voltage controlled oscillator (VCO)

RF Spectrum Analyzer

Always be careful to ensure signal input to spectrum analyzer is not too large

- What does a spectrum analyzer do?

- Attach wire-loop antenna and find radio stations

- Mix two RF signals and observe the expected spectrum

- Measuring amplitude of signal above background

- Save and export data

Soldering

- Soldering technique

- Cleaning iron tip

- Heat pieces to be soldered (hot iron, short time)

- Avoid cold solder joints

- Look for shiny and smooth result

- Tools of the trade: heatshrink tubing, desoldering pump, solder wick, wire strippers, soldering gun, heat gun, rosin flux

- Solder end of DB9 cable (using only 4 or 5 conductors) to practice stripping wire, using heatshrink tubing, and creating usable product

- Construct voltage divider on perfboard with BNC input/output connectors